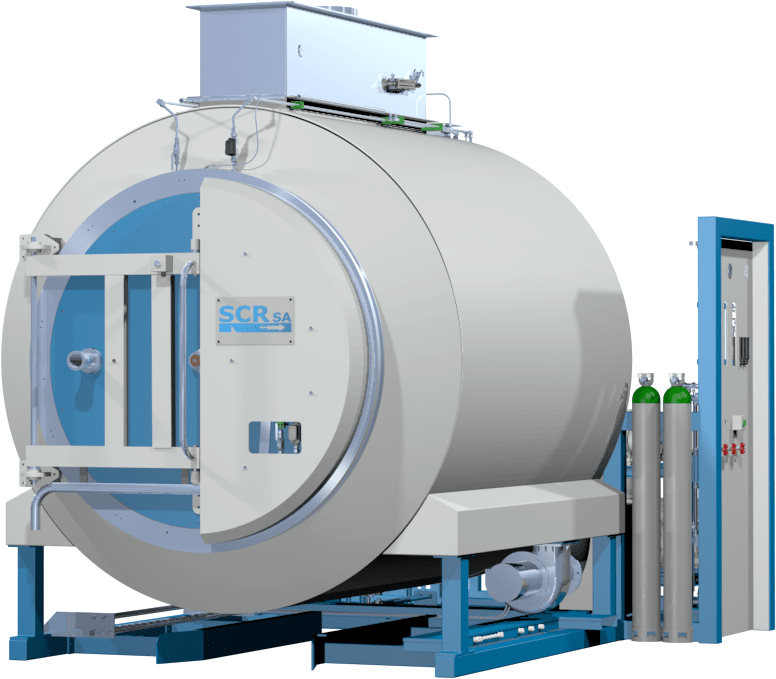

HVF nitriding / nitrocarburizing furnace

Fully- automatic, state-of-the-art comprehensive solution

- Optimizes and traces treatments, thanks to atmosphere control (Kn regulation)

- Delivers gas savings of up to 50% compared to conventional treatment

Perfect for aeronautical standard and Nadcap application compliance.

Treatment possibilities

- Nitriding

- Nitrocarburizing

- Low pressure nitriding

- Low pressure nitrocarburizing

- Pre-oxidation, post-oxidation

- Tempering with protective atmosphere

- Fast cooling

Types of steel that can be treated

- Nitriding steels

- Low-alloyed steels

- Stainless steels