SCR Supervision software

Supervisory Control and Data Acquisition system (SCADA)

The SCR supervision software can be adapted to any type of installation.

As it is optimized for heat treatment applications, it can manage a complete workshop, composed of a host of installations such as special machines, washing machines and industrial furnaces

Client-Server type architecture (multi-station)

MySQL Databases

ERP ready

Operation on PC under Windows 10/11

Documents

Last supervision project

Supervision and production management of a group of NABERTHERM heat treatment furnaces at our customer SFS in Switzerland.

For the sake of ecology, the load encoding principle has been completely redesigned to eliminate the paper tracking sheets that used to define the composition and positions of loads in the furnace.

Retrofit and replacement of a SCADA system on a SAFED heat treatment line at our customer SPIT.

Various options have been developed specifically for the customer to enable the conformity of parts to be monitored throughout the manufacturing process (heat treatment, surface treatment, etc.).

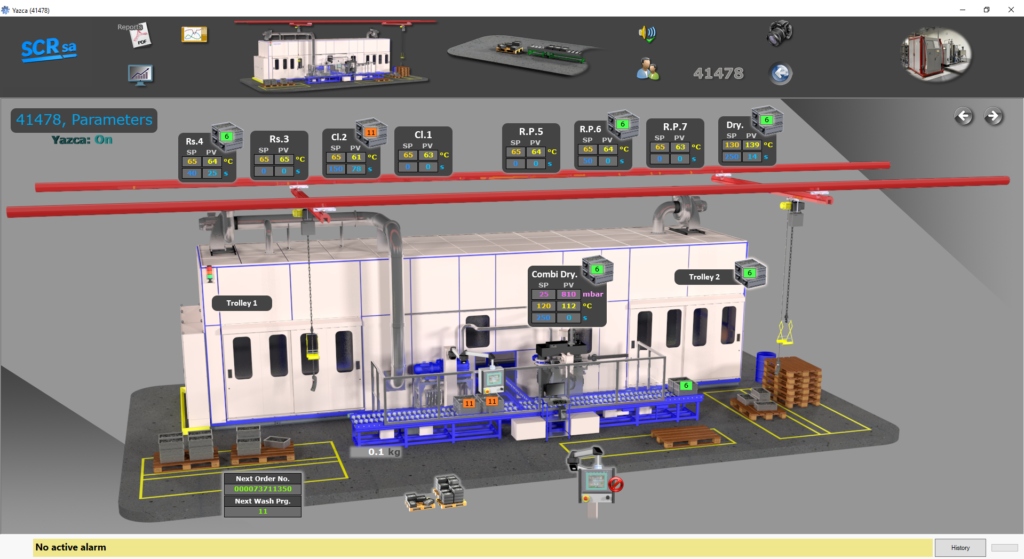

Supervision and production management of an automated parts washing line at our customer SFS in the USA.

It allows the monitoring and recording of all process data and production parameters allowing a complete analysis via our statistical analysis module.

Including our new “Task Reminder” module which allows the reminder and tracking of maintenance tasks to be performed on the installation.

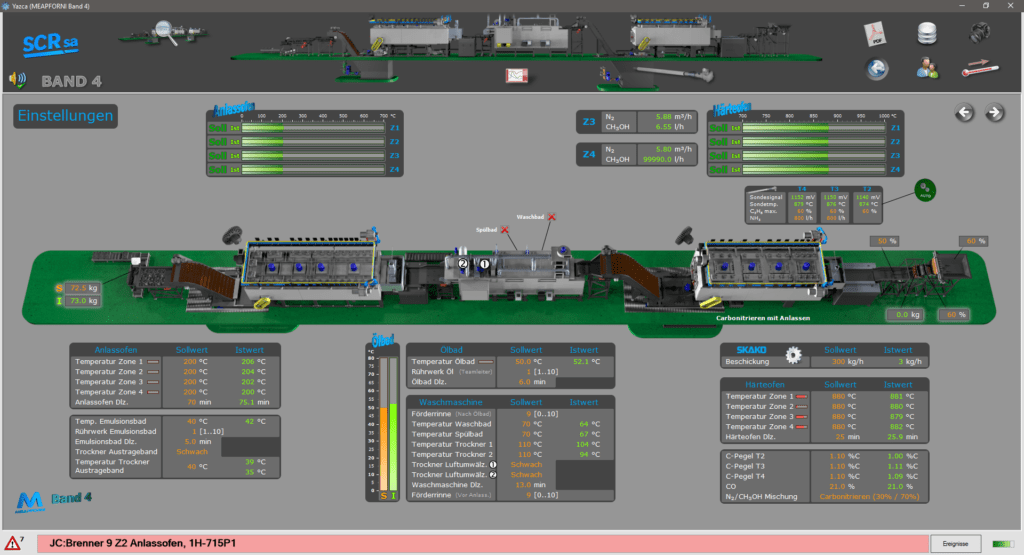

Supervision and production management of a MEAPFORNI heat treatment line equipped with a JOEST loading system, two ILVET washing machines, a tempering furnace (6 zones), an oil tank, and a tempering furnace (7 zones).

Installation of the SCR supervision software (in client mode) on a touch pad to facilitate maintenance operations on the line.

Supervision and production management of a complete SAFED-AICHELIN heat treatment line including the new “Load Tracker” function which allows to visualize the position of the loads at a precise moment.

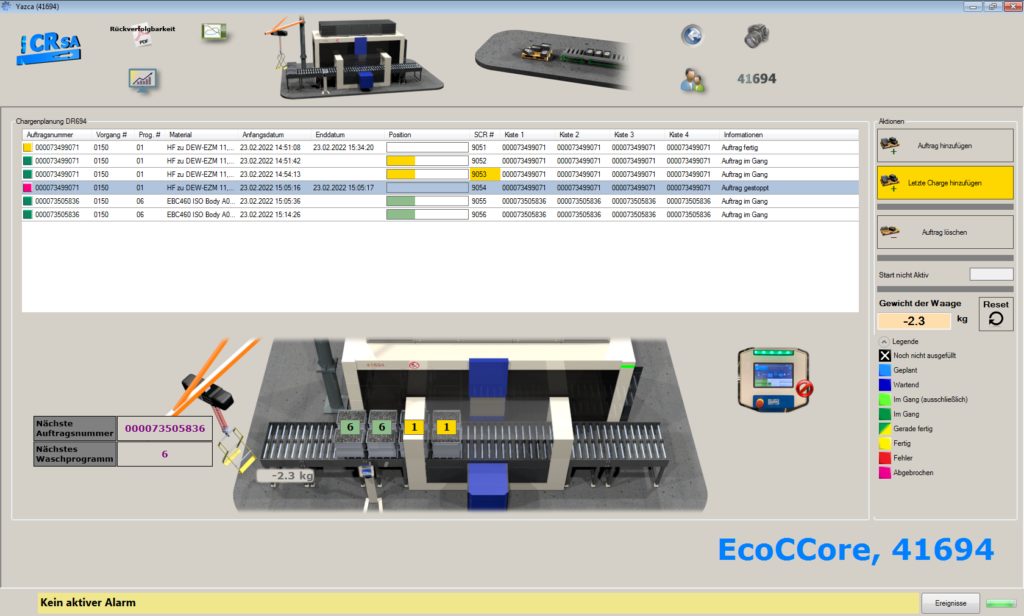

Supervising and managing the production of an ECOCLEAN washing machine.

Monitoring production and traceability of the batches of parts and recording all process parameters.

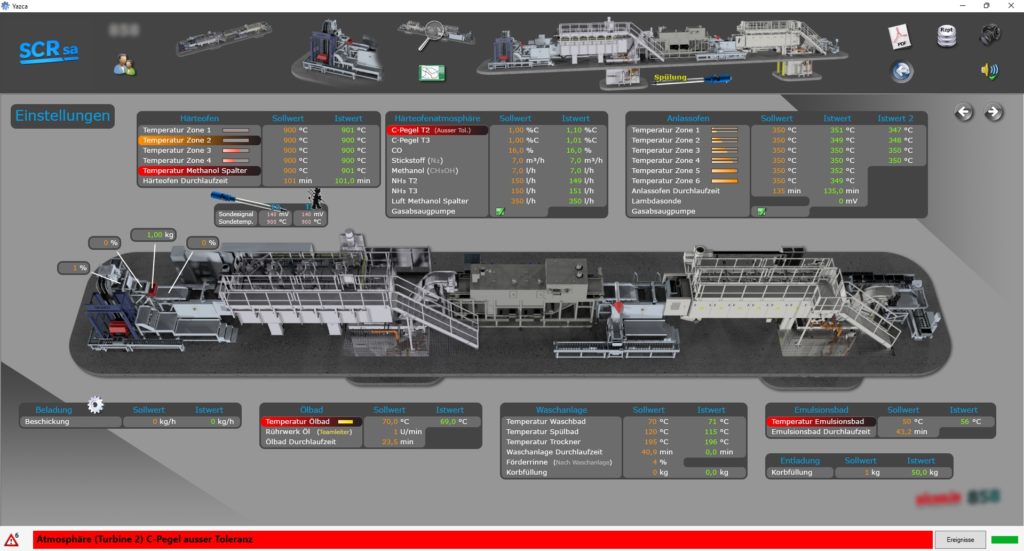

Supervising and managing the production of a MEAPFORNI heat treatment line equipped in order, with a SKAKO loading system, a tempering furnace, an oil bath, a washing machine and a tempering furnace followed by an emulsion bath.

Production monitoring can be carried out directly on the installation or remotely via a remote computer.

All data and history are backed up daily and automatically on a remote server.

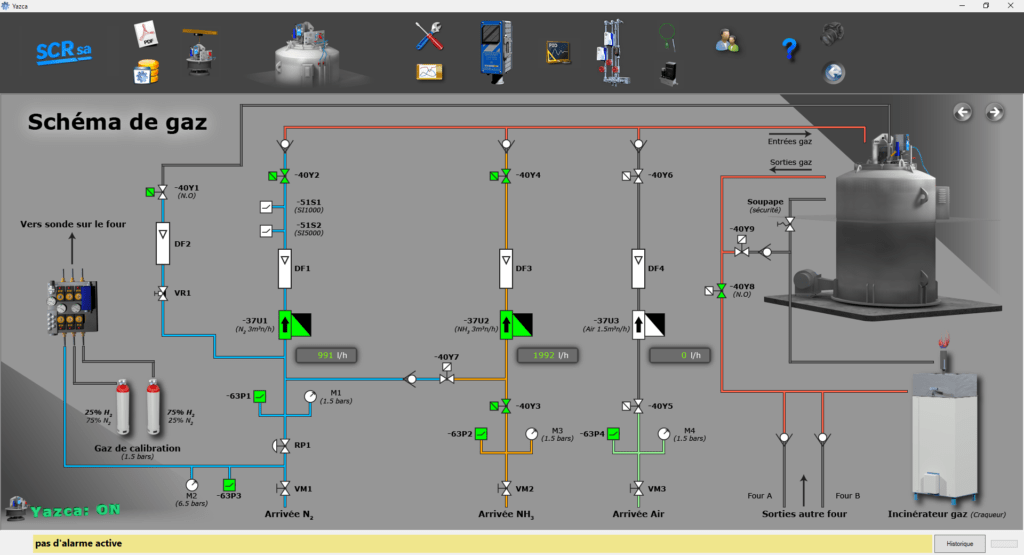

Viewing an interactive gas diagram on the supervision of a nitriding pit furnace at Bodycote.

This supervision was carried out during a complete retrofit of the installation which includes a Datanit probe for measuring and regulating the nitriding atmosphere to aeronautical standards, as well as an incinerator (cracker) used to eliminate the emissions from the furnace exit gases.